Home – Battery recycling

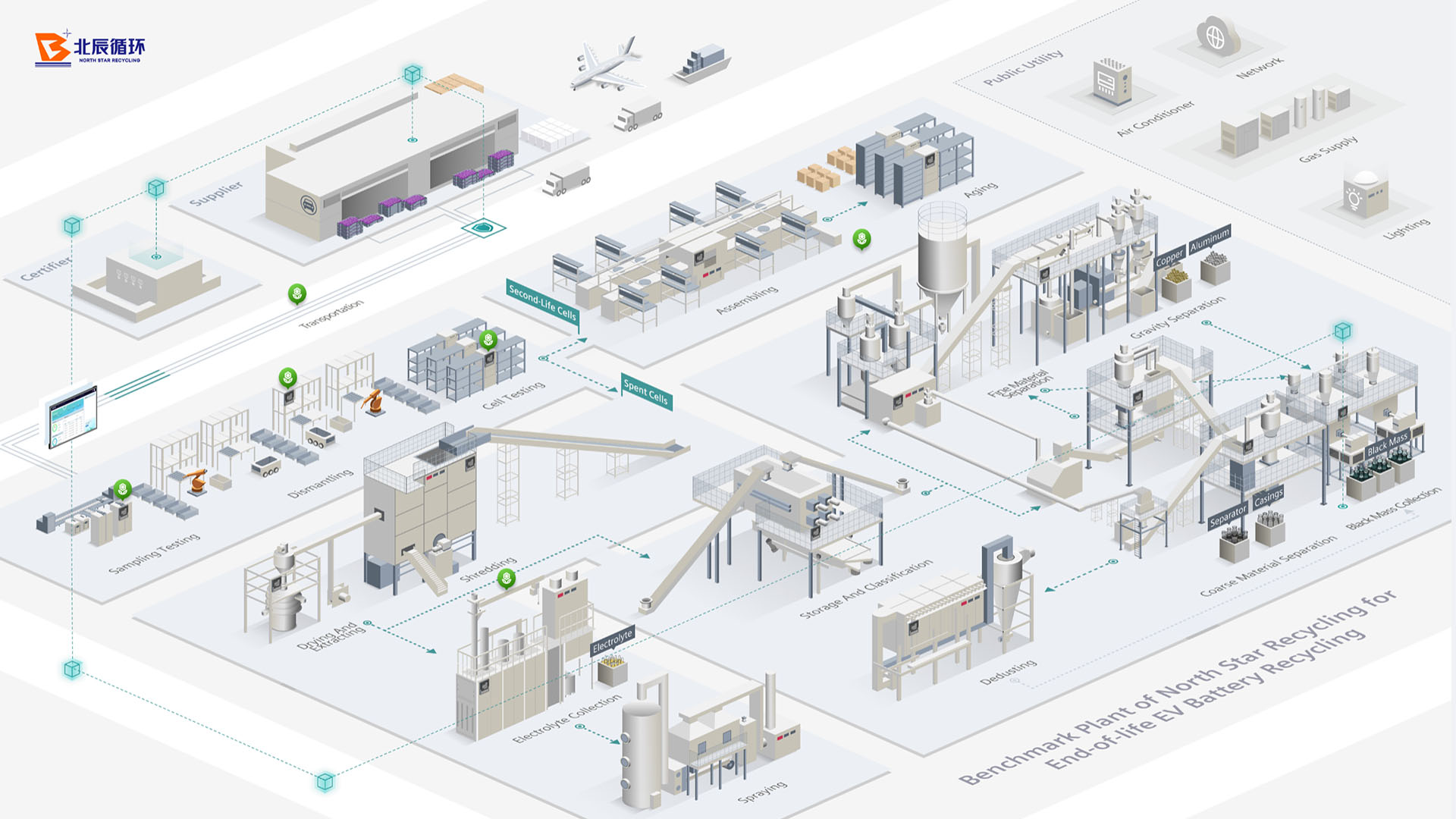

Automated 3D warehouse

Function

Pros

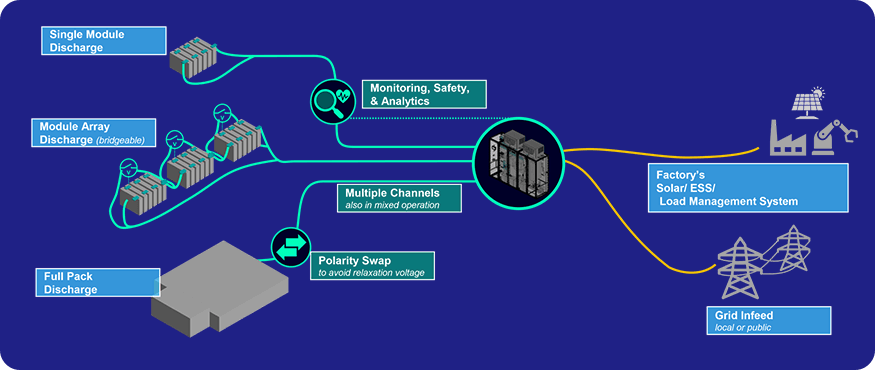

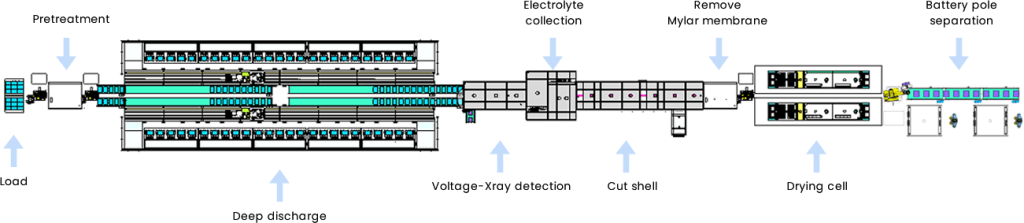

Deep discharge

Function

Ensures that any remaining electrical charge is removed, minimizing the risk of electrical hazards during handling and transportation. This is crucial for protecting workers and preventing accidents.

Highly configurable, built on a powerful and versatile DC-portfolio. Reliable and safe operation.

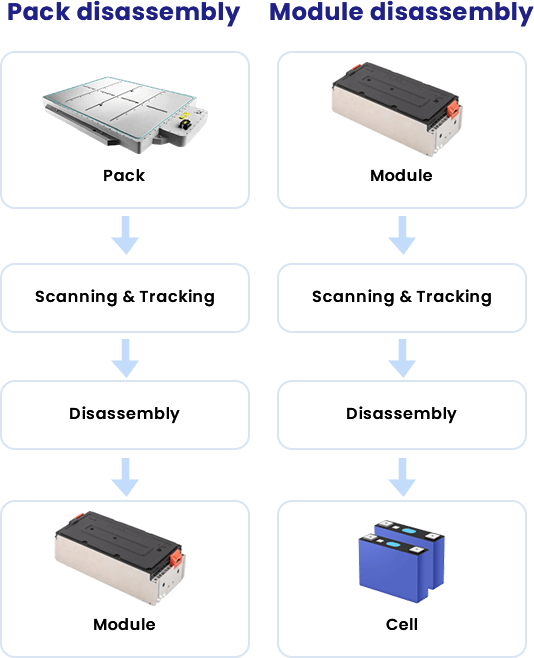

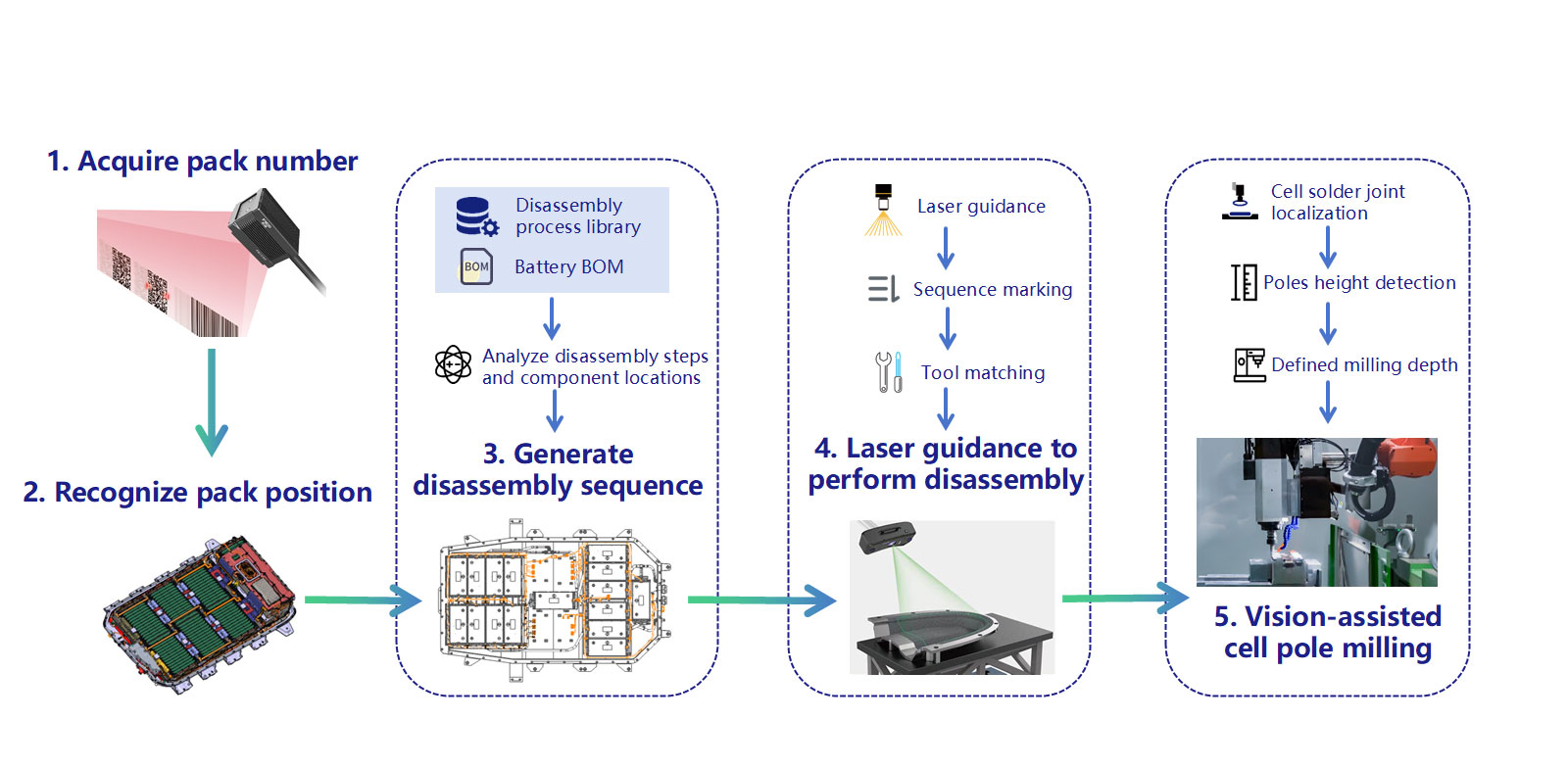

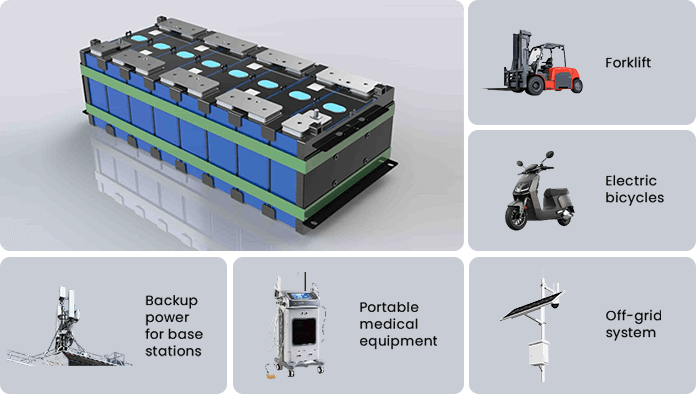

Battery pack/ Module

Function

Capable of performing various disassembly tasks, with a complete workflow that dismantles spent battery packs down to the cell level.

Pros

Maximizes the recovery of valuable components.

Increases economic benefits by approximately 30%.

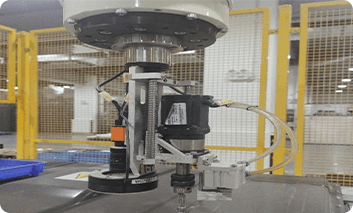

Equipped with precise robotic arms and tools capable of performing detailed disassembly actions.

Human-robot synchronized disassembly operations, where the machine handles repetitive tasks, significantly reducing labor intensity.

Features a modular architecture for easy maintenance, upgrades, and expansion of functionalities to accommodate different types of battery packs.

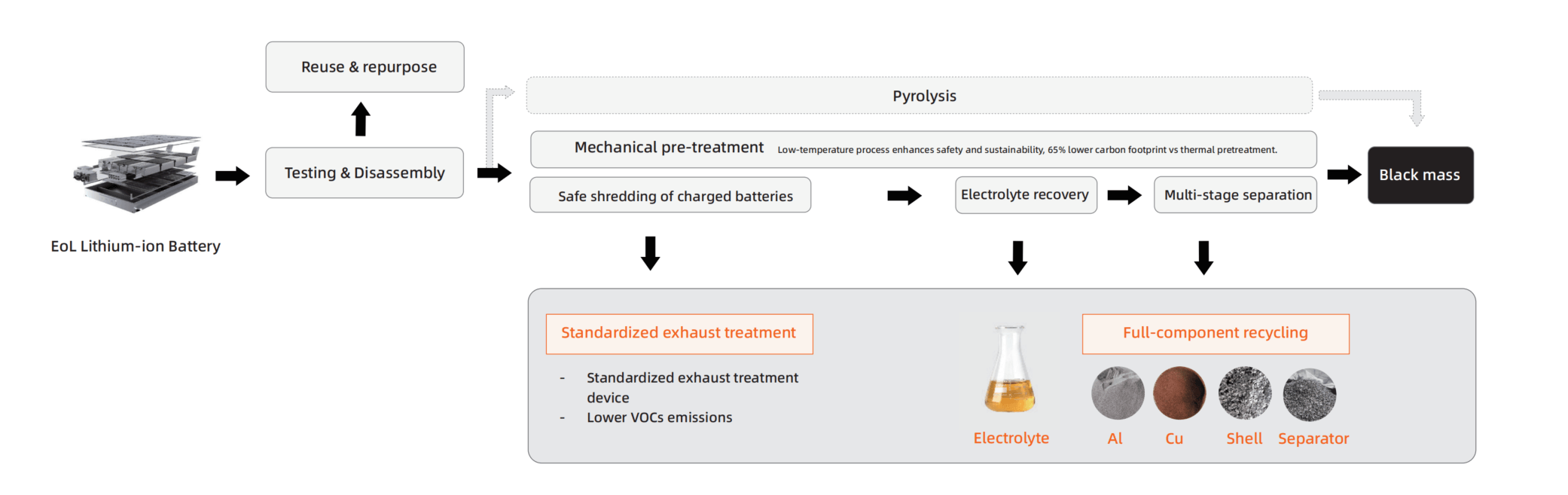

Precision disassembly

Environmental Protection

No pollution from physical discharge

Sealed inert environment (continuous nitrogen blowing) and negative pressure pumping environment

Pros

Real-time monitoring of temperature, smoke, and flame.

Rapid testing

Function

Advantages

Industry-leading rapid SOH detection of the battery pack, and detection without disassembling the battery pack.

Support reading of the battery pack data stream, and support reading of cell voltage and battery pressure difference.

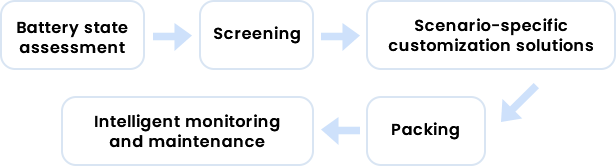

Reuse and repurpose

Pros

Compact design, small footprint.

Compliant with regulatory requirements, eligible for certification.

Short delivery cycle.

Cell packing

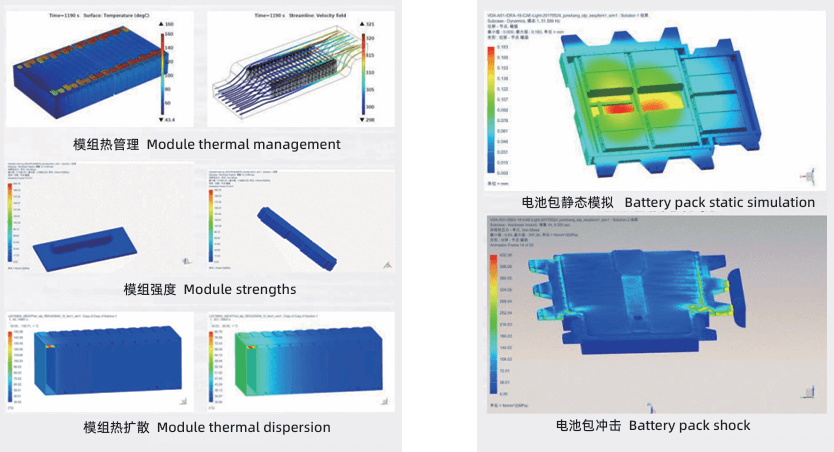

Integrated "Module-to-Pack" Simulation Platform: Supports end-to-end battery R&D through advanced modeling and validation.

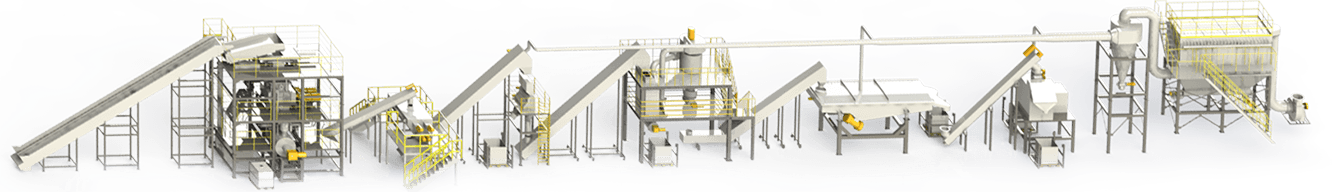

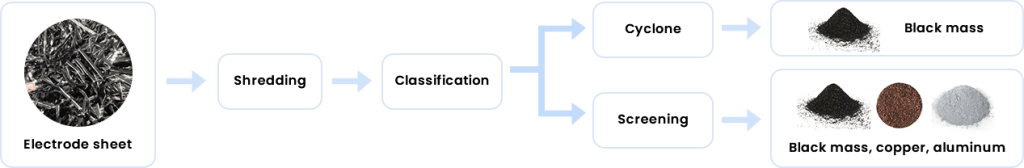

Electrode sheet

Pros

Compatible with processing both cathode and anode sheets

Short process flow, high production efficiency

Relatively low equipment cost

No pyrolysis process, low energy consumption

Environmentally friendly and non-polluting

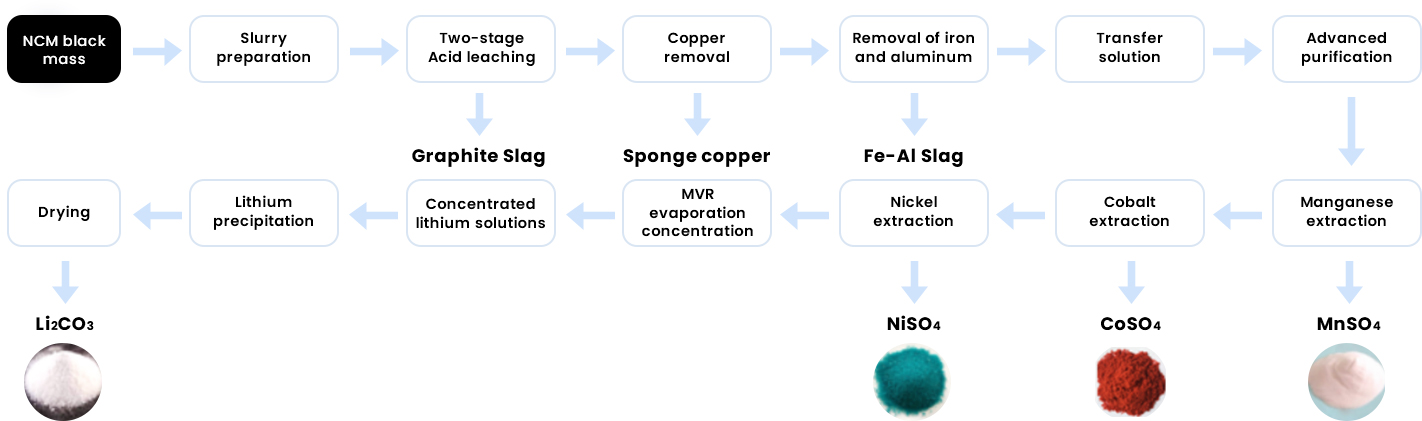

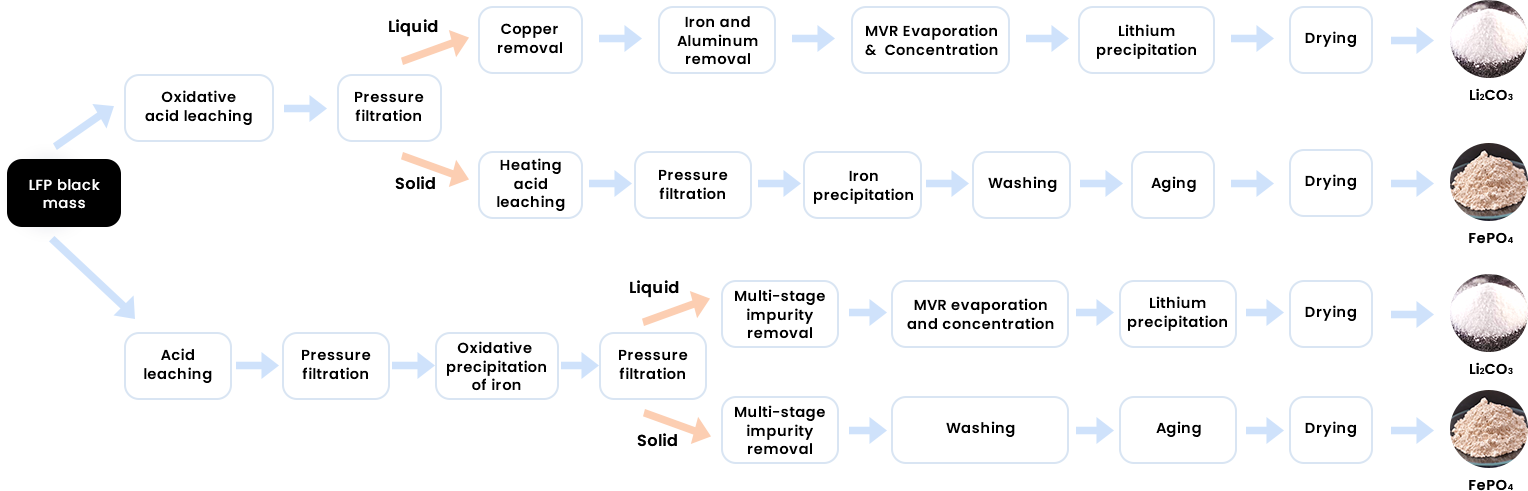

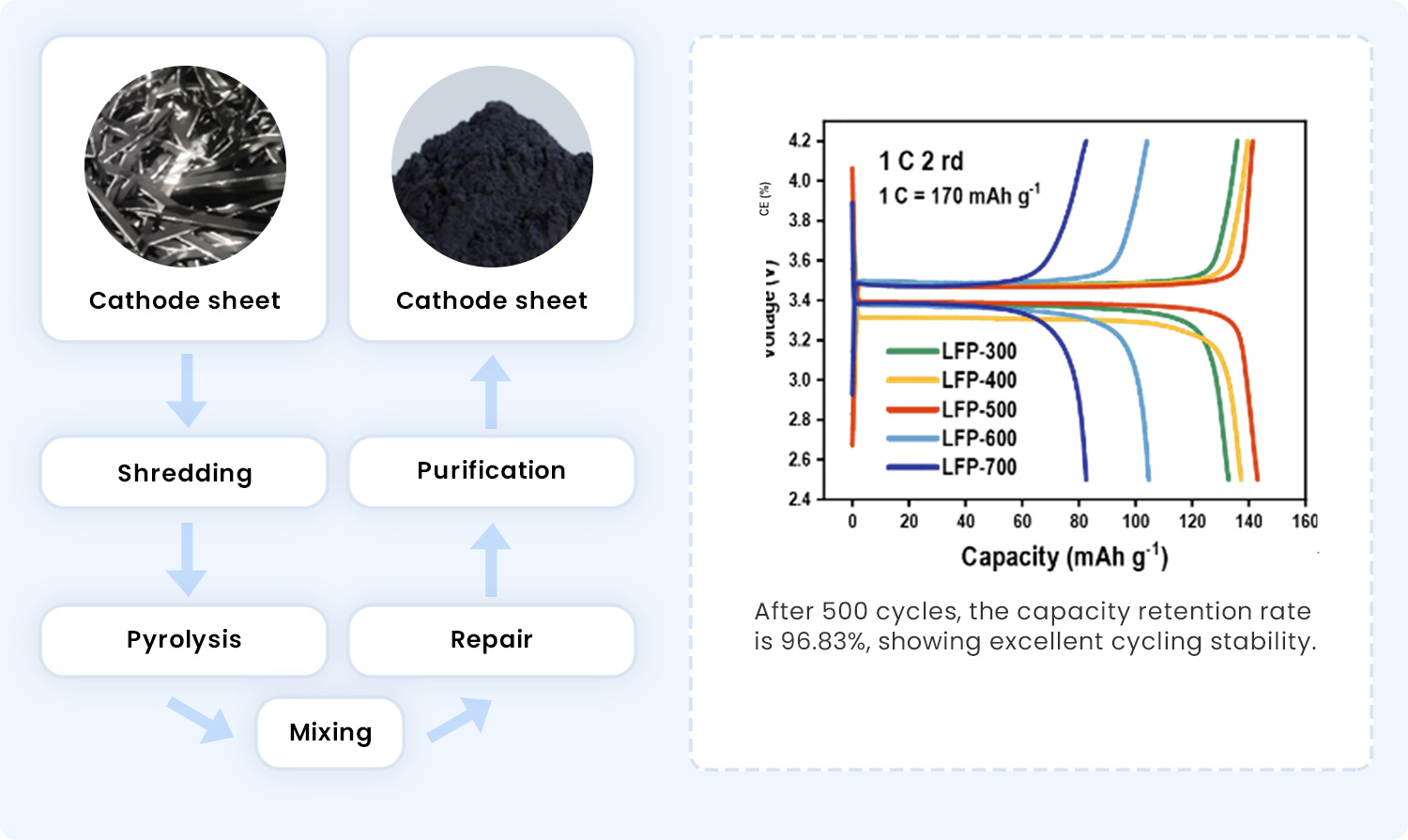

Cathode material regeneration

Function

Capacity retention rate of 96.83% after 500 cycles.

Product recovery rate > 99%.

Aluminum content in cathode materials < 100 ppm.

Pros

Capable of repairing retired battery cathode materials

Uniform carbon content and morphology, with low iron-lithium antisite defects

Excellent cycling stability

Repaired materials reach the level of commercial lithium iron phosphate materials

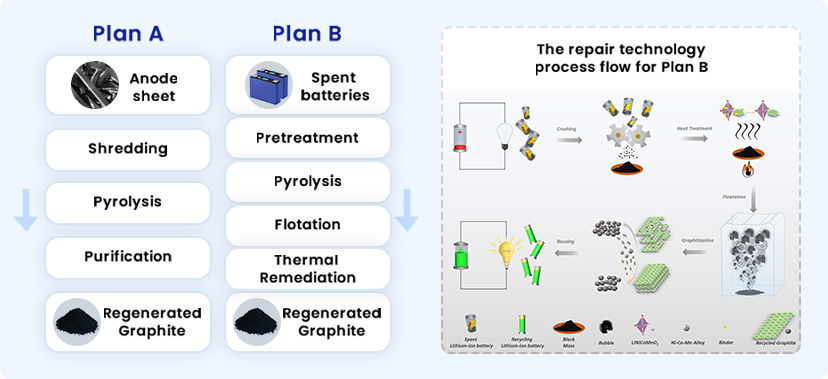

Anode material regeneration

Function

Achieve a graphite recovery rate of over 99%.

Initial week coulombic efficiency reaches 93.38%.

Specific capacity at 0.2C discharge is 360mAh/g.

Maintain a capacity retention rate exceeding 99.9% after 100 cycles.

Pros

The product can be directly reused through regeneration

High recycling rate, and stable performance.

Short process flow, high production efficiency.

Equipment use relatively low cost.

Can repair spent battery (wet) anode electrode material.