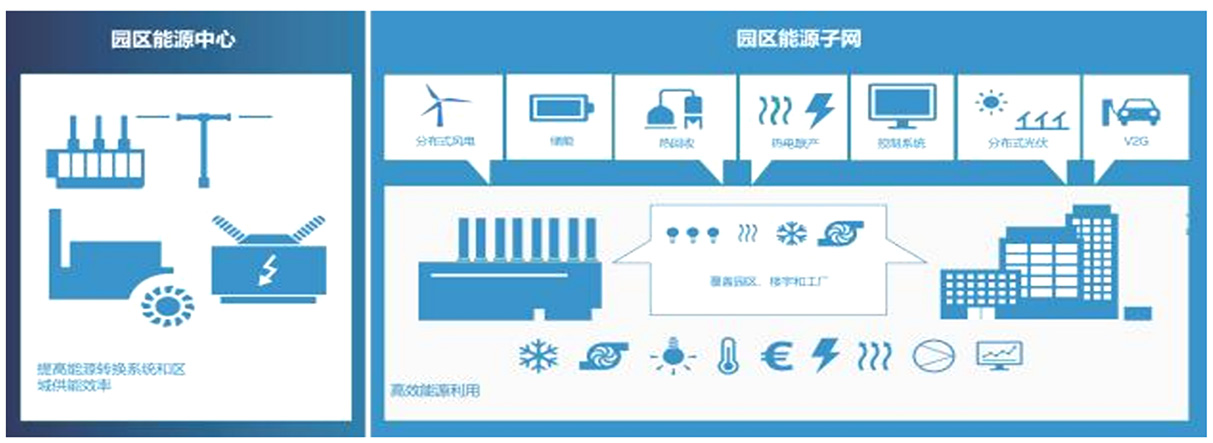

Source-Grid-Load-Storage synergistic regulation via smartenergy management system, establishing a tri-dimensional value system

for carbon neutrality, high-efficiency energy economics, and sustainable industrial development.

– Leverage peak-valley arbitrage and self-consumption of renewable energy to reduce energy costs and enhance investment returns

– Integrating multi-energy complementarity and intelligent control technologies to break through the limitations of traditional power system silos, while leveraging

energy storage regulation and demand-side response capabilities to enhance grid resilience

– Increase renewable energy penetration, optimize the energy mix, and achieve energy self-sufficiency alongside low-carbon transition